Trends come and go in every industry. Some end up being passing fads and others transform their respective industries. It is likely history will show that some of the current data center modularity trends added little value to the industry, while others helped sustainably transform it.

Modularity is one such data center trend that could forever change the future of the industry. There are a myriad of “modular” data center variations. Some of the options include:

- Containers: Referring to containerized data centers that are an all-inclusive “data center in a box.” Shipping container-sized modules that are fully functional data centers with single points of connection for power, IT, water, and sewer.

- Pre-planned stick built: Modularity refers to MEP/IT capacity building blocks that allow the next “chunk” of capacity to be added in definable and repeatable “bite sized-chunks.” The construction around this definition still refers to stick-built construction.

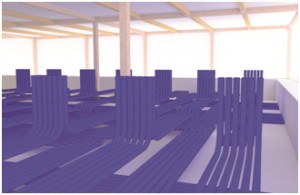

- Pre-Fabricated: Modularity refers to MEP components that are definable bite-sized chunks but are also in part pre-fabricated off site and brought in as fully functional and tested, ready-to-go MEP/IT components.

Glumac has designed over 4M sf of data center whitespace. In our opinion, all mission critical projects have critical project constraints (cost, efficiency, speed to market, quality, etc.) that might benefit from a modular approach. Traditionally, two of the biggest challenges with data center builds are capital outlay and speed to market. The traditional brick and mortar data center is generally expensive with long lead times. Modular builds can not only help a client save money and time, but also allow them to better match their inherent growth, enabling a more sustainable business model with less stranded capacity.

What are some of the advantages of a modular approach compared to a traditional build?

1) Improved Speed of Deployment:

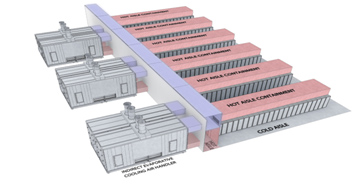

- Traditional construction methods are dependent on the determined project critical path. Certain aspects of a project build cannot start until others have been completed. In the data center industry, electrical buy-out and electrical construction is always on the project critical path. In theory, taking any item off the project critical path allows potential time to be saved (Figure 1).

- There are pre-assembled modular solutions that allow quicker time frames from order to deployment. As a standardized solution, modules can be ordered, manufactured, customized and delivered to the data center site in relatively short time frames. Any assembly work done off-site also means that the site construction can progress in parallel, instead of in series toward completion.

2) Potentially Higher Quality:

- Pre-manufactured components are typically manufactured in a controlled environment. Theoretically, this enables better working conditions, better QA/QC, pre-service testing and even commissioning of the component before shipping to the site. There are risks and costs involved in shipping. These need to be weighed as part of the decision making process.

3) Cost Efficiency:

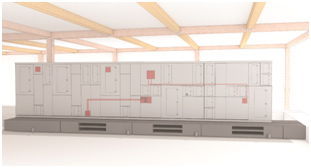

A modular data center build can also reduce upfront capital outlay and stranded capacity. The modular approach can provide an “as needed” deployment of IT, electrical and mechanical capacities to accurately match the clients current IT demands and allow for quick deployment when future capacity is required. Therefore, a modular build allows potentially smaller initial builds with a predefined roadmap building block strategy for subsequent additional MEP/IT capacity. Basically, build what you need when you need it (Image 3).

- With a repeatable, standardized design, it is easy to match demand and scale infrastructure quickly. The only limitations on scale for a modular data center are the supporting infrastructure at the data center site and the available land. Another characteristic of modular scalability is that modules can be easily replaced when obsolete, or if a technology refresh is in order.

- Potential Labor Savings: A manufacturing facility in Nevada may employ workers with an average wage multiplier of 1. If the data center was built in New York City, the cost of labor might have a multiplier of 1.4 or higher. Having components pre-manufactured in Nevada, would save the project 40% on the labor associated with the pre-manufactured equipment.

4) Controlled Technology Relevance

- Technology in data centers is ever evolving and changing at rapid rates. The modular approach to building “just-in-time capacity delivery” allows data center IT personnel to implement current technologies, while still allowing future technological advances to be utilized when future MEP/IT capacity is required.

In summary, Glumac’s Data Center group feels that sustainable modularity will help transform the data center industry and get users to think in terms of “build as required MEP/IT capacity.” Capacity additions/refreshes can have different looks, but data centers are just too expensive, IT needs are too dynamic and IT technology is too fluid to not consider the modularity approach to data center capacity decisions.

For further information on design approaches in the data center market, please contact Sam Graves at [email protected].